How to measure the conveyor belt guide bar?This is all the information about our conveyor belt guide bar. If you can’t find the specific guide strip you need here, you can contact our sales team for confirmation. Feel free to leave us a message at any time, and we will reply to you within 24 hours.

Phase 1: Identify the Guide Bar Type

There are two primary types of guide bars. The measurement process is slightly different for each.

Type A: V-Guide (or “V-Belt”)

This is a triangular-shaped guide that runs in a V-groove pulley. It’s the most common type.

Type B: Tracking Strip (or “Bead”)

This is a rectangular or trapezoidal strip, often used to trip a sensor or run against guide wheels on the side of the belt.

How to Measure a V-Guide

You need three key dimensions: Height, Width, and Angle.

- Height (H):

- Place the straight edge across the top of the belt, spanning the guide bar.

- Use your caliper or a ruler to measure the distance from the bottom of the straight edge to the highest point of the V-guide.

- This is the most critical dimension. It must fit snugly into the V-groove pulley without bottoming out or being too shallow.

- Width (W):

- Measure the total width of the guide bar at its base, where it meets the belt.

- Do not measure the top of the “V”; measure the widest point.

- Angle (θ):

- Most common V-guides have a standard 60-degree or 90-degree angle.

- You can use a protractor or an angle finder tool.

- Pro Tip: If you don’t have tools, measure the height (H) and the top flat width (if any). A 90° guide will have a height almost equal to half its base width. A 60° guide will be taller and sharper. A profile gauge is perfect for this.

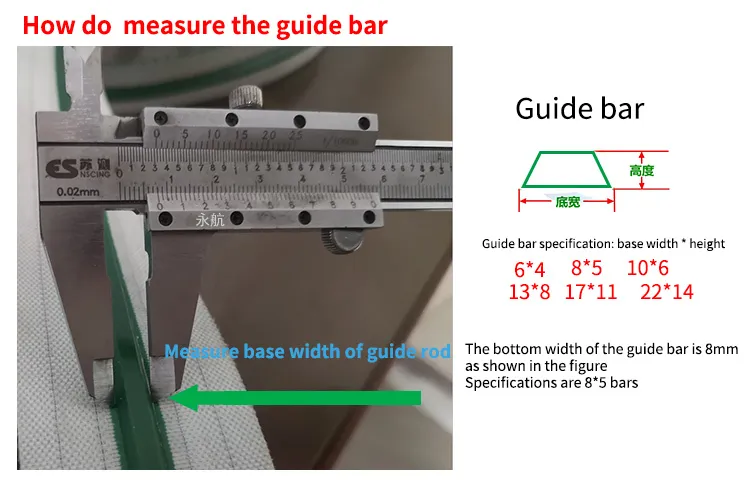

How to Measure a Tracking Strip

You need two key dimensions: Height and Width.

- Height (H):

- Just like with the V-guide, use a straight edge and caliper to measure from the belt surface to the top of the strip.

- Width (W):

- Measure the width of the strip at its base.

- Note if the sides are perfectly vertical (square) or slanted (trapezoidal).

Phase 2: Additional Critical Information

When you order a new belt or a guide bar to be applied, you will also need:

- Belt Thickness: Measure the overall thickness of the conveyor belt itself.

- Belt Ply and Material: Is it a PVC, rubber, urethane, or modular plastic belt? This determines compatibility with the guide bar material.

- Guide Bar Placement:

- On the Top or Bottom? Is the guide on the carrying side or the pulley side of the belt?

- Distance from Edge: How far is the center of the guide bar from the edge of the belt?

- Continuous or Segmented? Is it one long strip, or is it applied in segments with gaps?

Pro Tips and Common Mistakes to Avoid

- Don’t Guess the Angle: Assuming the angle is the most common mistake. A 60° guide in a 90° pulley will not track properly and will wear out extremely fast.

- Measure in Multiple Places: Belts and guides can wear unevenly. Take measurements at several points along the belt’s length (e.g., near the center and near both ends) to get an average.

- Use the Right Tools: A tape measure is better than nothing, but a Vernier caliper is inexpensive and provides the precision needed for a reliable measurement.

- Take Pictures: Use your smartphone to take clear, close-up photos of the guide bar from the side and top. Include a ruler or caliper in the shot for scale. This provides invaluable visual reference for the supplier.

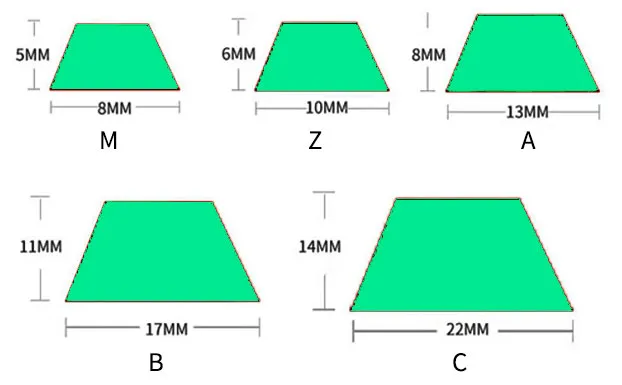

Below is our Yonghang Conveyer belt guide bar Specifications Table,For your reference and selection

Conveyer belt guide bar profile

| Type | M | Z | A | B | C |

| Width | 8mm | 10mm | 13mm | 17mm | 22mm |

| Height | 5mm | 6mm | 8mm | 11mm | 14mm |

| Roll/m | 50 | 50 | 30 | 30 | 30 |

| conveyor belt with guide bar | |||||||

| Cross section schematic diagram | Material | Type | Sizes | Color | Work Temperature | Min.turning diameter | |

| B*H/mm | ℃ | surface(mm) | bottor(mm) | ||||

| PVC | D6 | 6*4 | White / Green / Blue | -10~+70℃ | 40 | 30 | |

| D8 | 8*5 | White / Green / Blue | 50 | 40 | |||

| D10 | 10*6 | White / Green / Blue | 70 | 60 | |||

| D13 | 13*8 | White / Green / Blue | 100 | 80 | |||

| D17 | 17*11 | White / Green / Blue | 110 | 90 | |||

| D22 | 22*14 | White / Green / Blue | 180 | 120 | |||

| D30 | 30*16 | White / Green / Blue | 230 | 180 | |||

| R5 | 5*5 | White / Green / Blue | 50 | 40 | |||

| R10 | 10*10 | White / Green / Blue | 150 | 70 | |||

| R15 | 15*15 | White / Green / Blue | 200 | 90 | |||

| R20 | 20*20 | White / Green / Blue | 250 | 130 | |||

| PU | D13 | 13*8 | White / Green / Blue | -20~+80℃ | 100 | 70 | |

| D17 | 17*11 | White / Green / Blue | 110 | 90 | |||

| D22 | 22*14 | White / Green / Blue | 180 | 150 | |||

This table lists the specifications of the complete rolls of guide strips currently in our warehouse. If you have any other requirements, we can also provide them. Please feel free to contact us.

In addition, we also have the Conveyor belt accessory(skirt and cleats/baffle). Please refer to the user manual.

Conveyer belt Conveyor belt accessory(skirt and cleats/baffle Specifications Table

| Type | Material | Color | Min.turning diameter | u*t | Cross-Section |

| TS-20 | PVC | Green/white | 90 | 20*20 | |

| TS-30 | 100 | 30*30 | |||

| TS-40 | 100 | 30*40 | |||

| TS-50 | 120 | 35*50 | |||

| TS-70 | 150 | 40*70 | |||

| T10 | 80 | 10*10 | |||

| T20 | PVC | Green/white | 90 | 12*20 | |

| T30 | 100 | 12*30 | |||

| T40 | 100 | 14*40 | |||

| T50 | 120 | 16*50 | |||

| T70 | 150 | 35*70 | |||

| T80 | 180 | 35*80 | |||

| T90 | 200 | 35*90 | |||

| T100 | 220 | 35*100 | |||

| UT-20 | TPU | Green/white | 60 | 10*20 | |

| UT-30 | 60 | 10*30 | |||

| UT-40 | 60 | 10*40 | |||

| UT-60 | 80 | 10*60 |